Title: Stainless Steel Corrosion Caused by Microbiological Influenced Corrosion

Title: Stainless Steel Corrosion Caused by Microbiological Influenced Corrosion

Client Challenge:

This client encountered significant leaking in an unused 316-SS tubing manufacturing assembly

MCLinc approach:

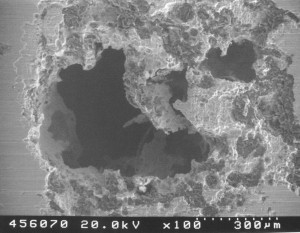

The 316-SS tube section with the visible corrosion was sectioned and then loaded into a Hitachi 4500 scanning electron microscopy (SEM) with energy dispersive x-ray spectroscopy (EDS). Both secondary electron and backscatter electron detectors were used for imaging. SEM images of the corrosion region on the sectioned stainless steel tube showed pitting type corrosion of the stainless steel where galvanic corrosion occurs in small active areas or pits. There was no evidence of dissimilar-metal galvanic corrosion, intergranular corrosion, erosion corrosion, chloride stress corrosion, or crevice corrosion. Note than an oxidizing environment is necessary for sustaining a passive film. Pitting corrosion is initiated or nucleated with a break down of this protective passive oxide film. Microbiological influenced corrosion (MIC) is one mechanism that can accelerate pitting corrosion where microorganisms are able to initiate, facilitate, and/or accelerate corrosion by depleting oxygen and break down the protective film. This process is usually accompanied by bio waste deposits. Backscatter imaging and energy dispersive x-ray spectroscopy confirmed the presence of these deposits. Micrographs also showed organic material associated with smaller and possibly newer corrosion regions. In order to determine whether bacterial biomass was present in the corrosion region of the stainless steel this area was swabbed with EDTA (ethylene diaminetetraacetic acid) to collect any DNA which may be present. The DNA was extracted from the swab using MoBio Power Soil DNA Extraction kit.

Outcome:

The presence of bacterial biomass was confirmed by amplifying the DNA extracted using a nested PCR approach. Several techniques have been applied to reduce the pitting type corrosion on 316 stainless steel; but, tube replacement has become a maintenance commonality in various industries. Some additional options to reduce pitting corrosion are: cleaning and using bactericides, protective coatings, and using high Mo alloys such as L-6XN or highly alloyed nickel alloy.